Mit mehr als 90 Jahren Erfahrung ist die Firma Dipl.-Ing. Dr. E. Vogelsang GmbH & Co. KG als Kunststoff- und Korrosionsschutzwerk tätig. Wir entwickeln mit 110 qualifizierten Mitarbeitenden in Abstimmung mit den Anwendern praxisnahe Innovationen zum Schutz verschiedener Infrastrukturen im Bereich der Telekommunikation, Energieversorgung oder auch der Gas- und Ölindustrie. Der Produktbereich umfasst Kabelschutzrohre in verschiedenen Werkstoffen, FiberSpeed® Mikrorohre, passive Korrosionsschutzsysteme, Dichtungstechnik und auch kundenindividuelle 3D-Druck Lösungen.

Zum Verbinden von FiberSpeed®-Rohren gleicher Abmessung in Zugangsnetzen und bei Abzweigen

Hier können Sie ab sofort die leeren Holztrommeln zur Abholung freimelden.

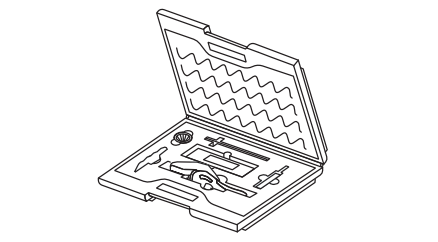

Der Werkzeugkoffer für die Installation der FiberSpeed® Monorohre und Verbundrohre.

„Rohre herzustellen ist einfach. Sie stets zu verbessern, ist die eigentliche Herausforderung.“